Rare Element Resources

Bear Lodge Project

Canadian NI 43-101 Technical Report

October 9

th

, 2014

10135-200-46 - Rev. 0

13-28

These samples were crushed to approximately 80% passing 2” and then screened to

remove the 2” material which became a reject stream. The minus 2” material was

further ground to minus 48 mesh. A sub-sample of Sample 1 was submitted to

bench-scale PUG processing using gravity separation only. The concentrate from

this gravity separation became Composite E. The final PUG concentrate, Comp E,

graded 2.66% REO, 41.0% SiO2, 12.9% Al2O3, and 1.16% CaO. 87.8% of the REO

was recovered in 65.0% of the weight with an upgrade factor of 1.35. Other

composites were generated by blending the eight samples to generate four

composites with steadily increasing TREO content as shown in Table 13.18.

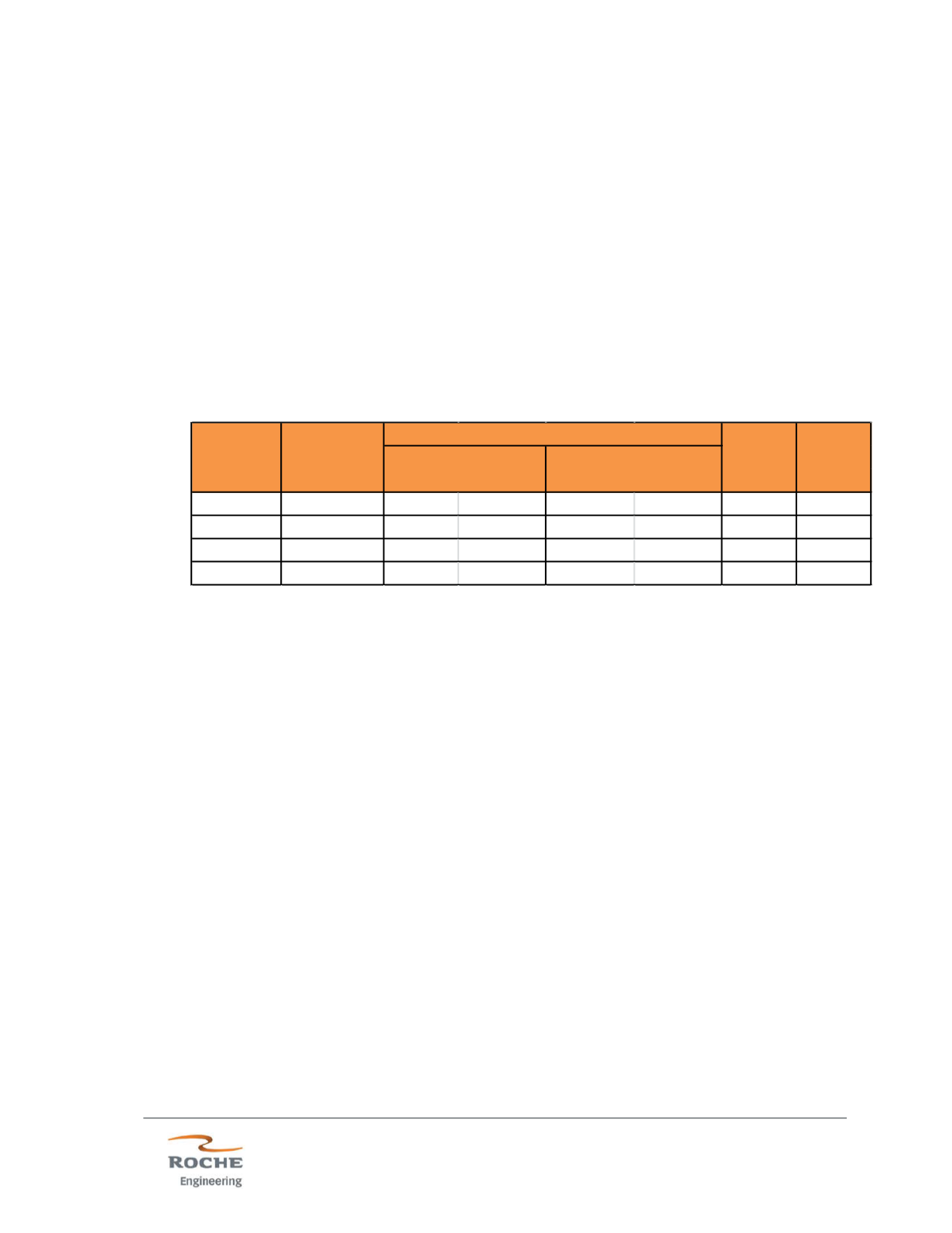

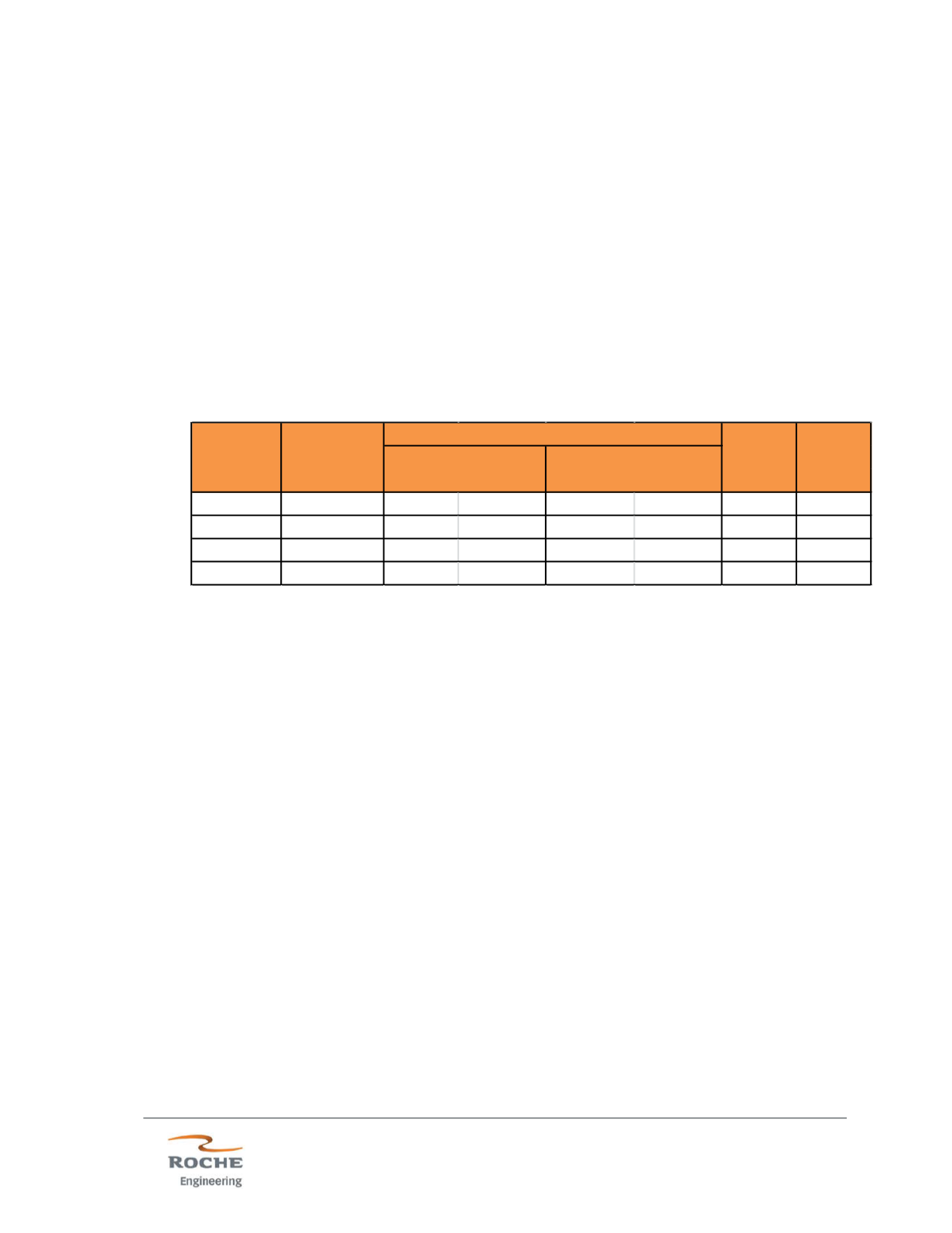

Table 13.18 - Compositing Ratios for Hydromet Testing Composites

(SGS Lakefield, 2014)

Comps B, C, D and E were processed at the PUG plant to produce mineral

concentrates for processing at the Hydromet pilot plant in February 2014. After the

mine plan was finalized, composites were assigned to represent various years of the

mine life as shown in Table 13.2.

Figure 13.10 illustrates the flowsheet that was simulated in the counter-current leach

pilot testing.

Composite

TREO

Wt

Name Content, % Sample Proportion Sample Proportion Total

Req. (kg)

Number

% Number

% %

Comp A 1.5% - 2.5% 1

33.3

5

66.7

100

95

Comp B 2.5% - 3.5% 2

57.1

6

42.9

100

90

Comp C 3.5% - 5.0% 3

66.7

7

33.3

100

60

Comp D 5.00%

4

66.7

8

33.3

100

60

Component