Rare Element Resources

Bear Lodge Project

Canadian NI 43-101 Technical Report

October 9

th

, 2014

10135-200-46 - Rev. 0

13-40

general, oxalic acid consumption ranged from 296 kg/t in PP5 (COMP B) to 121 kg/t

in PP6 (COMP C). When RE oxalates are not recycled, high losses of REEs may

occur in barren PLS.

The precipitation by element is presented in Table 13.22. Average acid consumption

was equivalent to 2.91 t/t concentrate. After precipitation, the precipitate is filtered

from solution and the solution is allowed to cool in a thickener where excess oxalic

acid is precipitated, settled out of solution and recycled to the beginning of the

precipitation circuit. Additional REE is captured in this recycle making the

precipitation efficiency close to 100% for most REE metals. Because excess oxalic

acid is recycled, a significant excess can be used in precipitation to insure a high

precipitation percentage of REE. A total retention time of 4 hours was sufficient to

precipitate the REE from the PLS for all ore types. Average thorium levels are from

0.5% to 2.0%, while uranium levels were below 35 g/t. Base metals are mostly below

detection limit, which indicates that high selectivity oxalic acid was successful against

most base metals. Note that the ore type has no impact on precipitation efficiency.

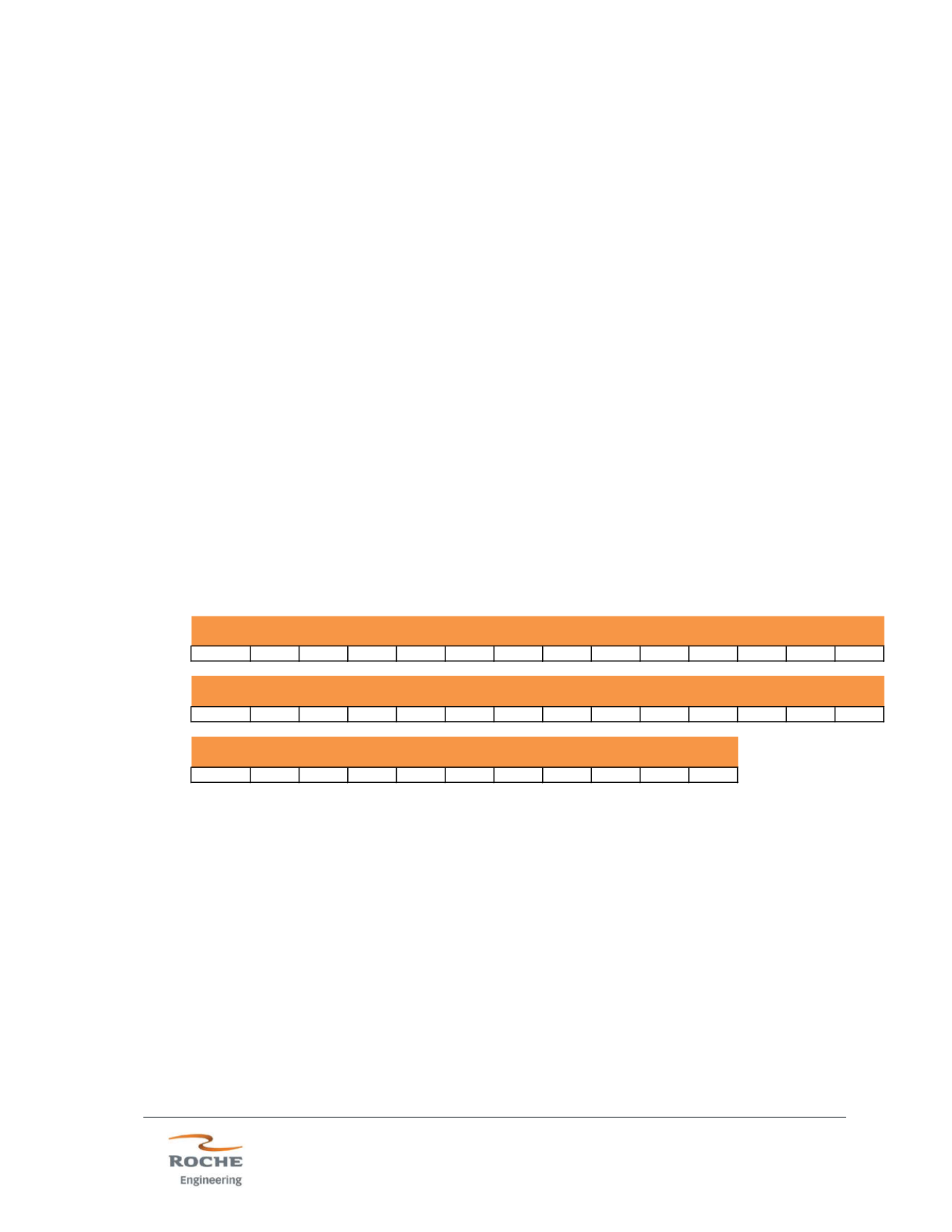

Table 13.22 - Precipitation with Oxalic Acid

(SGS Lakefield, 2014)

Consumption of oxalic acid can vary greatly depending on the composition of the

PLS. Aluminium and iron increase oxalic acid consumption by forming aluminum

oxalate and iron oxalate that are eventually sent to tailings. The low temperature

leach minimizes the leaching of iron which reduces oxalic acid consumption.

Figure 13.15 shows the precipitation pilot plant unit that was used for testing in 2013.

La

Ce

Pr

Nd

Sm Eu

Gd

Tb

Dy

Ho

Y

Er

Tm Yb

% % % % % % % % % % % % % %

98% 100% 100% 100% 100% 100% 100% 99% 100% 99% 100% 99% 93% 99%

Lu

Sc

Th

U Al

As

Ba

Be

Ca

Fe

K Mg

Mn

Mo

% % % % % % % % % % % % % %

93% 92% 100% 4% 3% 43% 15% 1% 45% 0% 10% 0% 0% 29%

Na

P Pb

Si

Sr

Ti

V

Zn TREE LREE HREE

% % % % % % % % % % %

1% 1% 42% 14% 7% 14% 4% 0% 99% 99% 100%