37

High-Grade Mineral Resource

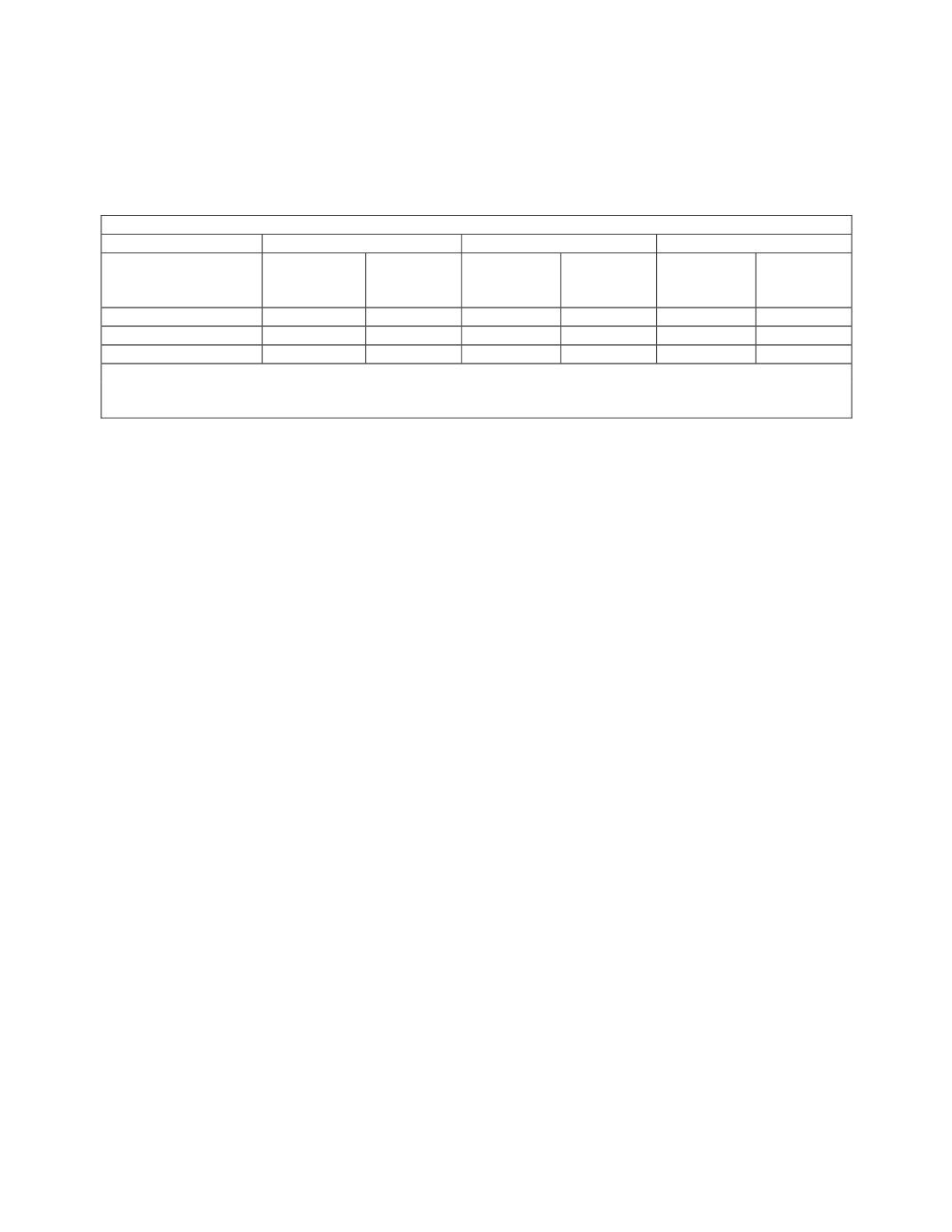

High-grade Mineral Resources, which are those resources above a cutoff grade of 3% TREO, are

particularly important, since they are the focus of mining in the first nine years of production. The high-grade

Mineral Resource is summarized below. It occurs predominantly on the flank of Bull Hill, which contains 78% of

the Measured and Indicated, high-grade resource.

Summary of High-Grade Measured and Indicated Mineral Resource

(1)

effective as of October 9, 2014

(2)

Cut-off Grade

(3)

Bull Hill

Whitetail

Total

Resource

Classification

Tonnes (in

millions)

Average

Grade (%

TREO)

Tonnes (in

millions)

Average

Grade (%

TREO)

Tonnes (in

millions)

Average

Grade (%

TREO)

Measured

1.5

5.01

-

-

1.5

5.01

Indicated

4.0

4.43

0.7

3.93

4.7

4.36

Measured & Indicated

5.5

4.59

0.7

3.93

6.2

4.52

(1) Bull Hill Mine includes both the Bull Hill and Whitetail Ridge deposits from NI-43-101 (2014).

(2) Inclusive of previously reported Mineral Reserves under NI 43-101 (2014).

(3) Cut-off grade of 3.0%.

Quality Assurance

The Mineral Resource estimate was completed by Mr. Alan C. Noble, P.E., principal engineer of Ore

Reserves Engineering, and is based on geological interpretations supplied by the Company to Ore Reserves

Engineering and subsequently modified by Ore Reserves Engineering. Mr. Noble is an independent Qualified

Person for the purposes of NI 43-101 and verified the data disclosed herein.

Rare Element’s field programs prior to 2014 were carried out under the supervision of Dr. James G. Clark,

formerly the Company’s Vice President of Exploration. Dr. Clark is a senior geologist and previously was

exploration supervisor for Hecla Mining Company during the late 1980s and early 1990s, and was responsible for

that company’s exploration of Bull Hill and the Bear Lodge district, and its initial discovery of the Bull Hill resource

area. In 2014, John T. Ray, the Company’s Chief Geologist and a Qualified Person as a SME Registered Member,

directed our exploration efforts. Mr. Ray was a consultant to Newmont Mining Company during its operations in

the Project area from 2004 to 2010. A detailed QA/QC program was implemented for the 2007 through 2013 drill

programs. The QA/QC program was organized by Dr. Jeffrey Jaacks. Drs. Jaacks and Clark verified the sampling

procedures and QA/QC data delivered to Ore Reserves Engineering. They share the opinion that the data are of

good quality and suitable for use in the Mineral Resource estimate.

Metallurgy and Mineralization

The Mineral Resource size is sensitive to an assumed cut-off grade and to metallurgical operating costs.

The mineable pit includes the known Measured and Indicated (M&I) Mineral Resource as disclosed in the Technical

Report and is inclusive of the adjacent Whitetail Resource Area that extends towards the northwest. The current

mine plan for the Bull Hill Mine will allow mining for approximately 38 years and beneficiation and processing for

approximately 45 years.

A PUG plant, located within the Project area, is designed to maximize concentration of the rare earth

minerals and produce a mineral concentrate using a crushing, screening, and gravity separation process depending

on the material type. The PUG process is designed to concentrate the rare earth-bearing fines and reduce the

physical mass. There are areas of the mineable pit that contain variable amounts of weathered oxide material or

oxide-carbonate (OxCa) mineralized material, and that contain variable grades of stockwork mineralization adjacent

to the higher-grade material. Each of these material types will have a different upgrade percentage and mass

reduction in the PUG circuit. The mining plan anticipates exploitation of a distinct high-grade zone early in the

Project that will allow for preferential mining in the initial years of the mine. Low and mid-grade material will also

be mined and stockpiled for future PUG processing.